Curious about multi-needle embroidery machines but not sure how they differ from single-needle machines? Here’s what you need to know if you’re thinking about upgrading.

Multi-Needle vs Single Needle Embroidery Machines

What is a multi-needle embroidery machine?

As its name implies, a multi-needle embroidery machine is an embroidery machine with… multiple needles! But, what would you need more needles for? Is it worth the extra expense to purchase one of these machines?

The main benefits of multi-needle embroidery machines vs single-needle

Multiple needles means multiple thread colors without swapping

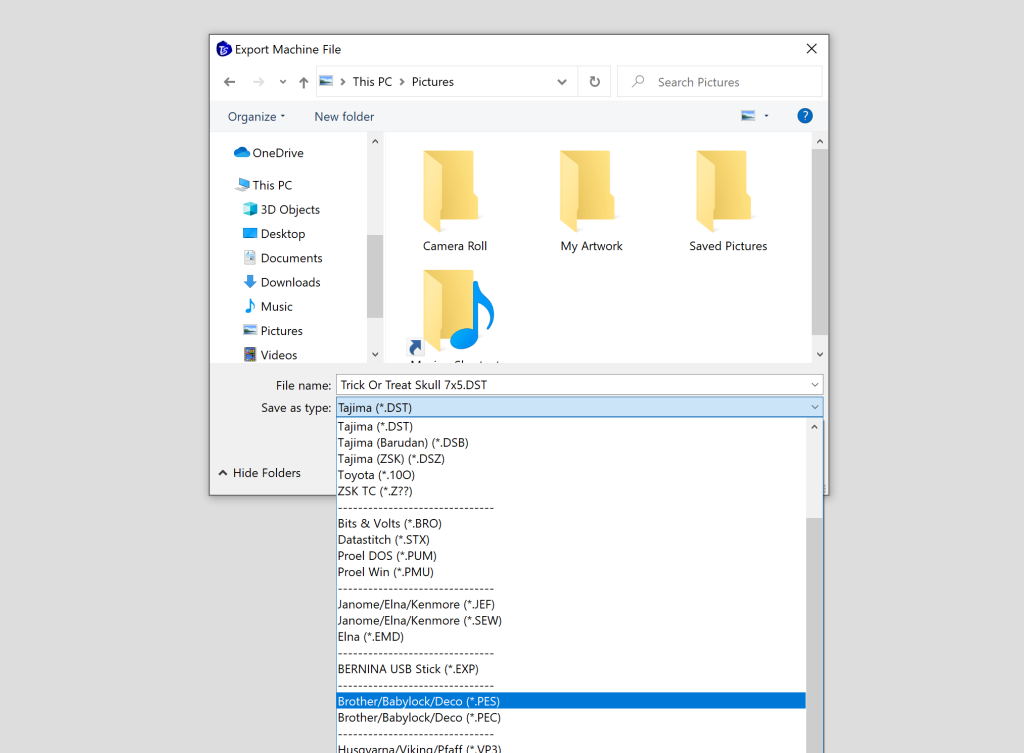

If you’re stitching a design with a lot of colors on a single needle machine, you’ll be spending a ton of time rethreading it. However, with a multi-needle machine, this is not a problem. You can pre-thread each needle, and the machine will automatically swap to the next needle when the design calls for a color change.

This is a huge time-saver if you’re starting to embroider a lot of garments, and it’s honestly, a must-have if you’re thinking about starting an embroidery business. Now, all that time you would have wasted on rethreading can be spent hooping the next item, helping customers, or packing up orders instead.

Multi-needles have tubular and free-arm embroidery options

While having to rethread the machine isn’t exactly fun, it does not limit what you can embroider. It just makes things more time-consuming. That’s why the biggest negative to a flatbed machine is actually that it does not have a free arm for tubular embroidery and hat hoops.

Full disclosure, this is not a multi-needle exclusive feature. There are a few single-needle machines that have free arms, and they will allow you to embroider on structured caps, socks, and the sleeves of hoodies. However, they aren’t cheap, and honestly, by the time you pay for one of those you may as well buy a small multi-needle machine instead.

While the Brother PRS100 is an excellent embroidery machine, it is single-needle-only.

For the same price, you could purchase the 4-needle Janome MB-4SE or the Elna 940.

Both are excellent machines and have multi-needle benefits at no additional cost.

Investing in a machine with a free arm opens up all kinds of new possibilities for embroidery that set you apart from the competition. This includes intricate sleeve embroidery designs, socks, structured hats, bulky duffle bags, shoes, and pretty much anything else that will fit under the head of the machine.

Your machine is always ready for any garment

An often overlooked benefit of a multi-needle set-up is that it’s always ready to sew any garment! Let’s say you have an 8-needle machine for your business. You could have 6 needles set up as sharp points for things like jackets or shirts, but then have the last two needles set as ballpoints for knitwear. No daily setup is required.

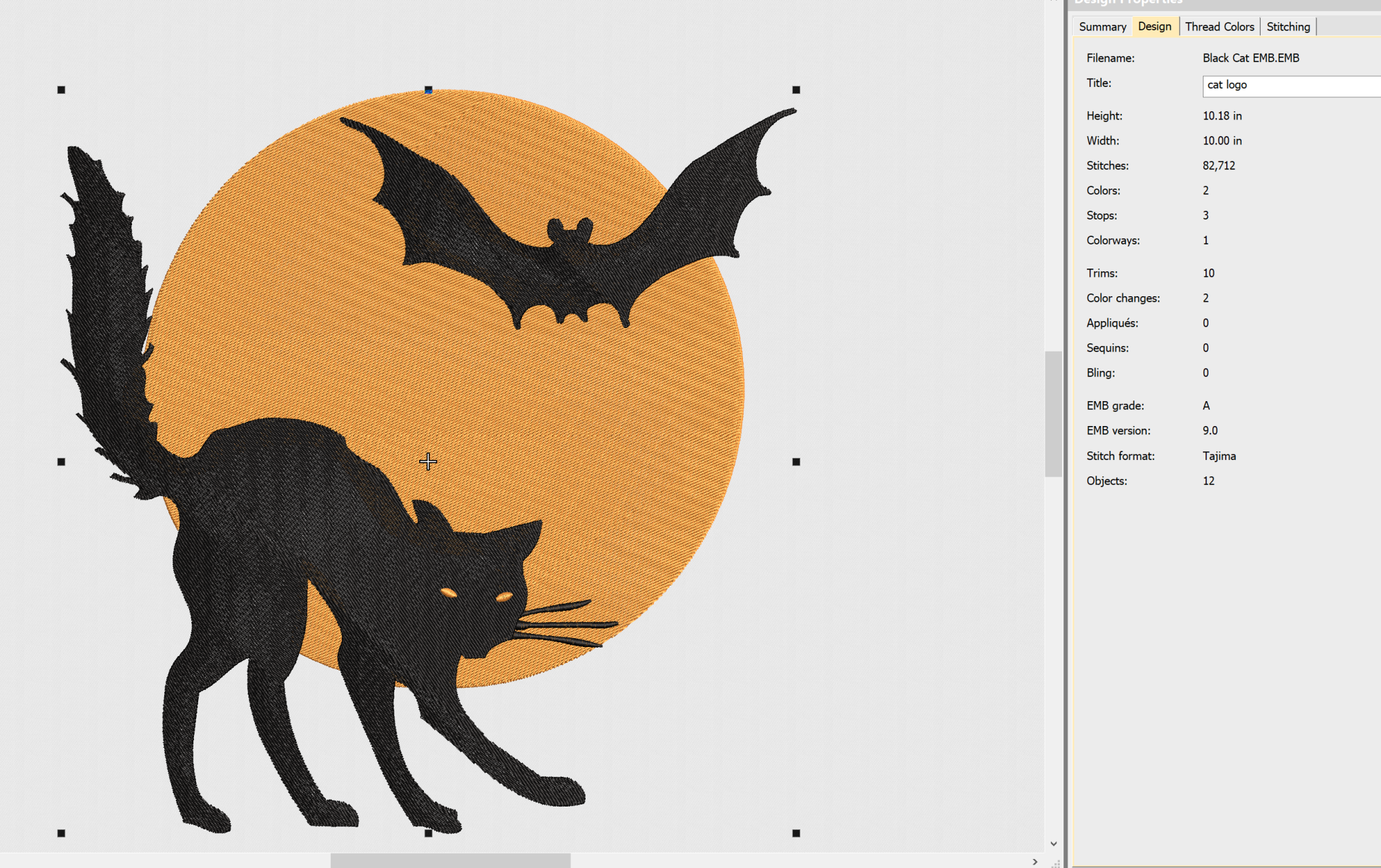

The largest hoop sizes available

Multi-needle machines are serious business, and they will always have a larger hoop size when compared to a single needle. So, if you dream of creating beautiful, large jacket designs – a multi-needle machine is for you.

Home flat-bed machines tend to cap out at around 10″ x 6″ in size, but a multi-needle provides much more space. The SWF MAS has a 16.7” x 10.9” embroidery field, and industrial machines go even larger, sometimes up to 47″ x 20″ in. However, be aware that a machine with an embroidery field that large will be immensely expensive.

Click here to see the SWF 12-needle embroidery machine

Hooping a multi-needle machine is also much easier

Because of the way the machines are designed, hooping is a much faster process. Using clamps or fast frames, you can quickly get the next item ready to stitch while the machine does its job. There is also way more space under the needle, so you aren’t fooling around with bulky items trying to get them to fit either. Hoops for these machines also tend to be more robust and stable compared to flimsier flatbed frames.

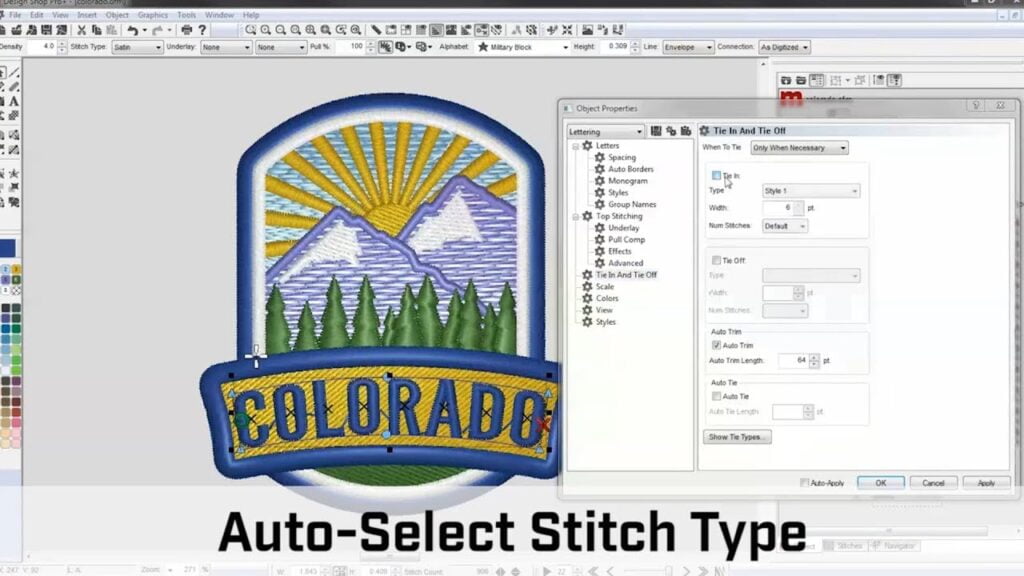

Multi-needle machines are much faster than flatbed machines

While a flat-bed machine tends to cap out speed-wise at about 600-750 stitches per minute, a multi-needle machine is much faster. These machines typically operate at around 800-1,000 stitches per minute. While that may not seem like a big deal, it is if you’re trying to mass-produce garments for a big order.

Single-head vs multi-head machines

I’ve seen some people use the terms multi-needle and multi-head interchangeably, but these are different things. A multi-needle machine is a machine that has multiple needles. A machine like this will only be able to embroider one garment at a time. Though you will be able to embroider multiple colors without rethreading.

For example, if you have an 8-needle machine, then you will be able to stitch out a single, 8-color design without needing to rethread the machine (unless the thread runs out, of course.)

Multi-head machines also are multi-needle and can do the same, BUT they can also embroider on multiple items at once. So, if you have a two-head embroidery machine with hat hoops, you’ll be able to embroider twice as fast, making two caps at once.

SOME of these machines are also dual-function. A dual-function machine actually allows you to embroider different designs on each head at the same time. However, these types of machines are very expensive, and it may actually make more sense to buy multiple single-head machines depending on what kind of orders you are fulfilling.

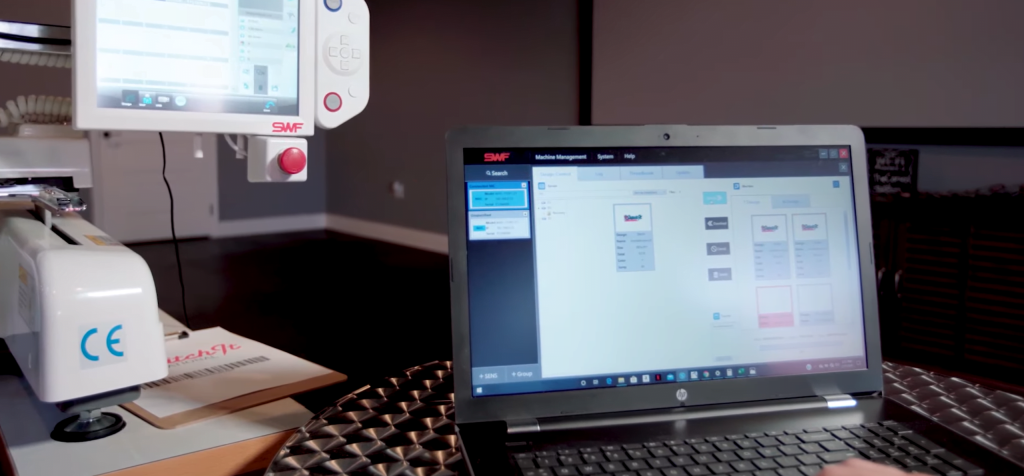

Did you know you can actually network multiple single-head machines together? As your business grows, you could acquire a second single-head machine, like the pictured SWF 12 needle, and then network it together with the first one. This is actually super easy to do, and will likely end up being more affordable than a multi-head machine.

PLUS, it has the added benefit of allowing you to use each machine independently to stitch separate designs (for multiple orders) or connect them so that both machines stitch the same design (for large orders).

In short, there is a LOT to think about if you’re considering a multi-needle machine. Hopefully, this article will be helpful as you decide what machine is right for your needs.

Happy Crafting!

Barb, our resident quilter and embroidery aficionado, weaves a thread of creativity through our collection. Serving as the curator of machine embroidery content, Barb infuses each design with a touch of her artistic expertise. The free embroidery patterns you discover on our site often bear the mark of Barb’s craftsmanship. Let’s get crafting!