Whether you’re looking to find out how much you should be charging for your own services, or you’re looking to get custom embroidery work done, this article has the answers! While embroidery pricing can get complicated fast based on different factors, these guidelines should help you budget your projects.

In general, you can expect to pay $0.50 per 1,000 stitches for custom embroider, BUT there are a lot of factors that go into that price which can quickly add up. Below I’ll go over what impacts the cost of embroidery.

Pricing Models for Embroidery Work

Pricing models can differ from provider to provider, and this can sometimes make it hard to compare costs. Here’s what to know about pricing models for custom embroidery work and how to negotiate a better price.

Per Stitch Pricing vs. Flat-Rate Pricing:

- Per Stitch: Directly correlates costs with the number of stitches in the design. Suitable for simpler designs but may become expensive for intricate logos. One solid square inch of embroidery is approximately 2,000 stitches for reference, but things like outlines and shadowing can quickly multiple stitch counts!

Negotiation Tips for Better Deals:

- Explore volume discounts for larger orders. Evaluate package deals that include design digitization, setup fees, and embroidery at a bundled price. Many shops have “packages” ready to go because it’s easier for customers to understand and makes them more ready to pull out their credit cards.

Understanding Additional Charges:

- Clarify the scope of setup fees, whether they are one-time or recurring. Ensure that setup fees cover the necessary preparations for machines and materials. Is digitization of your design included or an extra charge? Make sure the invoice includes ALL the charges to avoid any surprises that can ruin your budget.

Transparent Communication:

- Request detailed quotes outlining all costs, including materials, labor, setup fees, and any additional services. Transparent communication ensures clarity on what is included in the quoted price. If they don’t seem to want to provide this, pick a new shop.

These are some basics for understanding embroidery costs, but below we’ll detail the specifics of what will cost you more, and then some cost-saving tips for increasing your profit margins per item.

What factors influence embroidery cost?

The Item You Want to Embroider On

Some items are just harder to embroidery on than others! Embroidery is not always a straight forward procedure depending on the fabrics involved, and custom embroidery shops must account for extra time and materials. Similarly, items that have small details, or that require specialized equipment, such as embroidered patches, may come at an up-charge.

The Fabric You Want to Embroider On

Embroidery on fleece or velvet, for example, may require additional stabilizer, machine adjustments, or time to set up the projects. While it is possible to embroider on almost any fabric, the difficulty in doing so can vary greatly and some fabrics are more unforgiving than others!

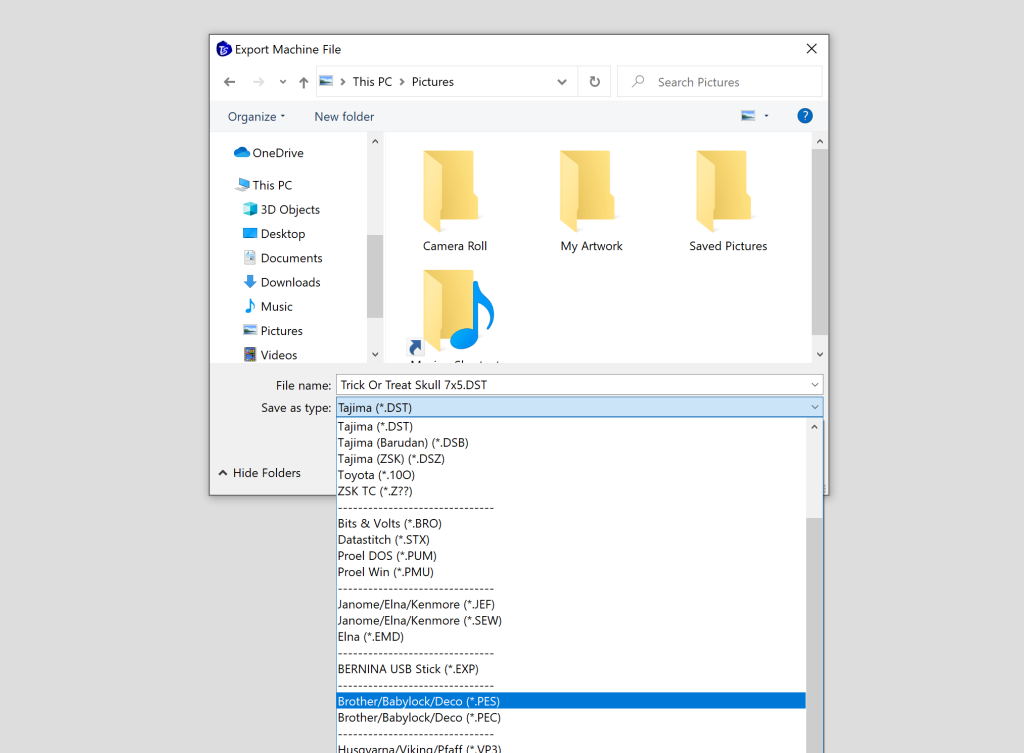

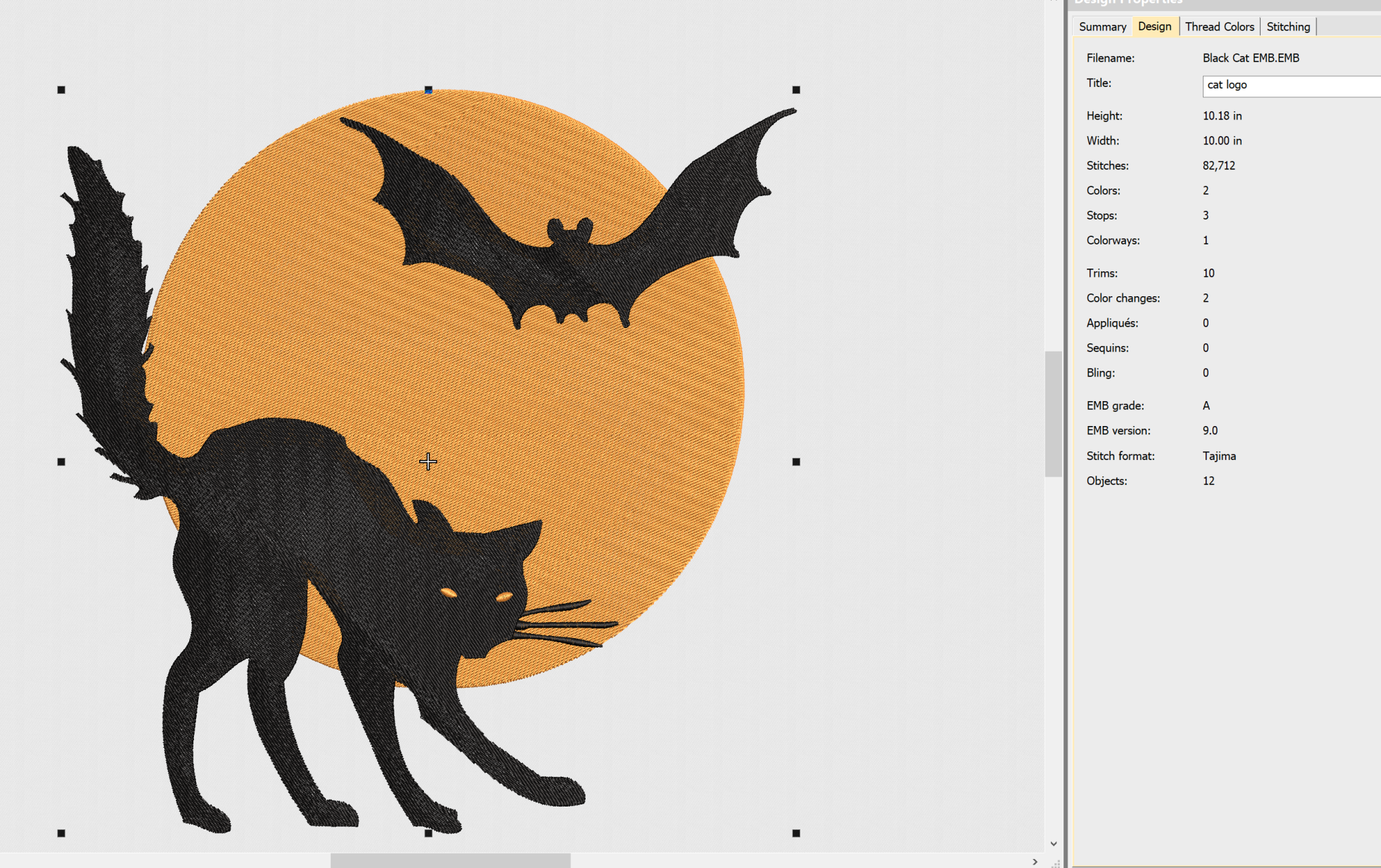

The Complexity of Your Design

In order for a design to be stitched out it must first be digitized. Designs with more intricate details will take a lot more time and skill to digitize, and while this is a one-time fee, you’ll pay more for this initially.

In addition, the more intricate a design is the more stitches it will have. More stitches means more thread, and you’ll also need to pay for the additional materials and production time required to stitch it.

The Quantity You’ll Have Embroidered

In most cases, you’ll be purchasing embroidered items in bulk, and typically, the more you buy the better deal the shop will give you. This is because they can sell more of the same item at one time and they’re willing to take a bit of a price cut to make more money in one go.

If your budget allows for a bigger upfront investment in garments, this is the best way to cut your cost per-item. However, it’s important to know whether you’ll be able to actually sell all of these items! You don’t want to end up sitting on a ton of inventory that does not sell.

If your business is new, a better strategy may be starting with a smaller amount of items and once a design has proven itself, then invest in a larger bulk order to raise your profit margins.

The Use of Specialty Materials

If you want to use specialty threads like metallic or glow in the dark, there is usually an additional charge for these. This is typically in the range of $0.40 to $0.50 per item.

Metallic threads cost more money for starters, but they are also a pain to work with, as we covered in our embroidering with metallic thread article. Metallic threads are kind of a pain to use, and shops may charge you more money for the inconvenience.

How to Reduce the Cost of Custom Embroidery

Looking to reduce the cost of your custom embroidery project? Here are a few places you can cut the fat to get more for your money and increase your profit margins.

Order in Bulk

This is by far the best way to save money on custom embroidery jobs. It’s standard practice to give increasing bulk discounts and the more items you can order the more money you’ll save. If your budget is limited, consider starting with a more limited line of custom items so you can order more at once.

Simply Your Designs and Scale Down

While having a busy and huge design looks cool, it’s going to cost you a lot of money. Sometimes minimalism is good, and if you need to focus on preserving your budget it’s also a smart business move. Streamline your designs and scale them down if you can.

Choose Cost-Effective Materials

Using standard threads like cotton or rayon and avoiding more expensive specialty materials can automatically save you $0.50 to $1.00 per item. When you’re working with thin margins, this can add up quick. You can also opt for cheaper fabrics which are often easier to work on, such as cotton.

Ask About Package Deals

Some shops may have package deals available. If they do, this is often a great way to save money. They’ve set-up these packages because they are efficient and cost-effective for them, and they will be for you as well.

Barb, our resident quilter and embroidery aficionado, weaves a thread of creativity through our collection. Serving as the curator of machine embroidery content, Barb infuses each design with a touch of her artistic expertise. The free embroidery patterns you discover on our site often bear the mark of Barb’s craftsmanship. Let’s get crafting!