Yes! Embroidery on fleece can be done, but there are some special considerations that need to be made. In this article, we’ll discuss the challenge of using machine embroidery on fleece, and make some recommendations that will make your job a little easier!

The Unique Challenges of Machine Embroidery on Fleece

Fleece fabrics often have a plush pile or nap, this plush surface can make it challenging for embroidery stitches to penetrate the fabric consistently, leading to uneven results. In addition, fleece can be thicker than other fabrics, impacting the penetration of your embroidery machine’s needle and causing irritating tension issues.

You may also experience distortion of your finished design due to the stretch and give of the fabric, because fleece is also very sensitive to thread tension. Below you’ll find some tips to help you make your fleece machine embroidery projects a success!

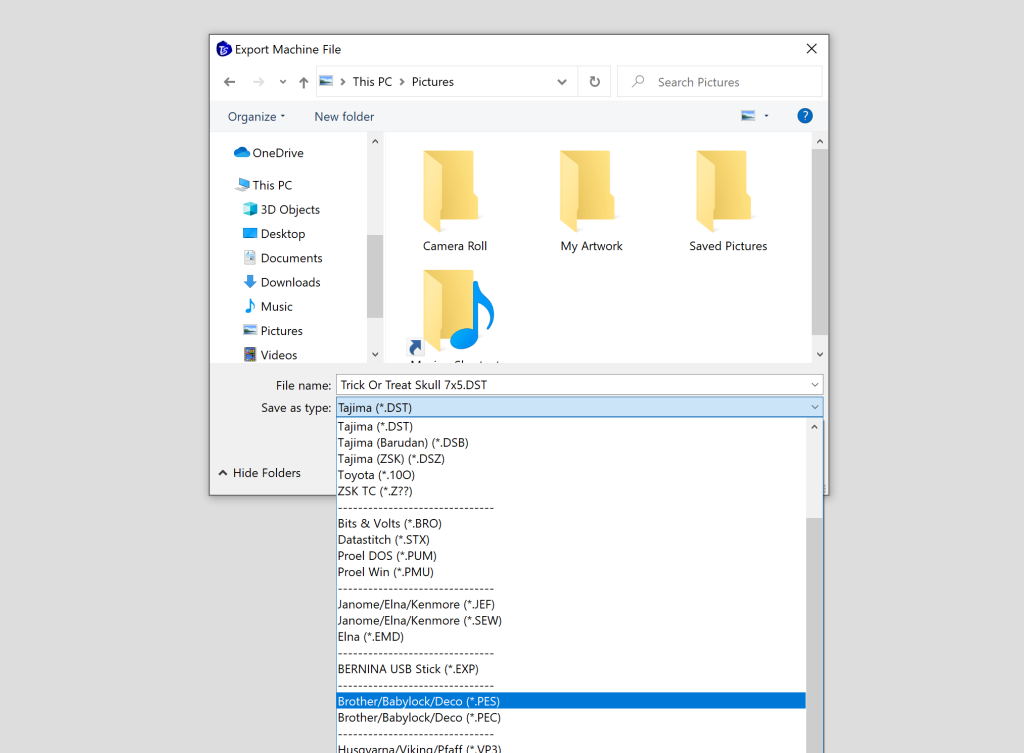

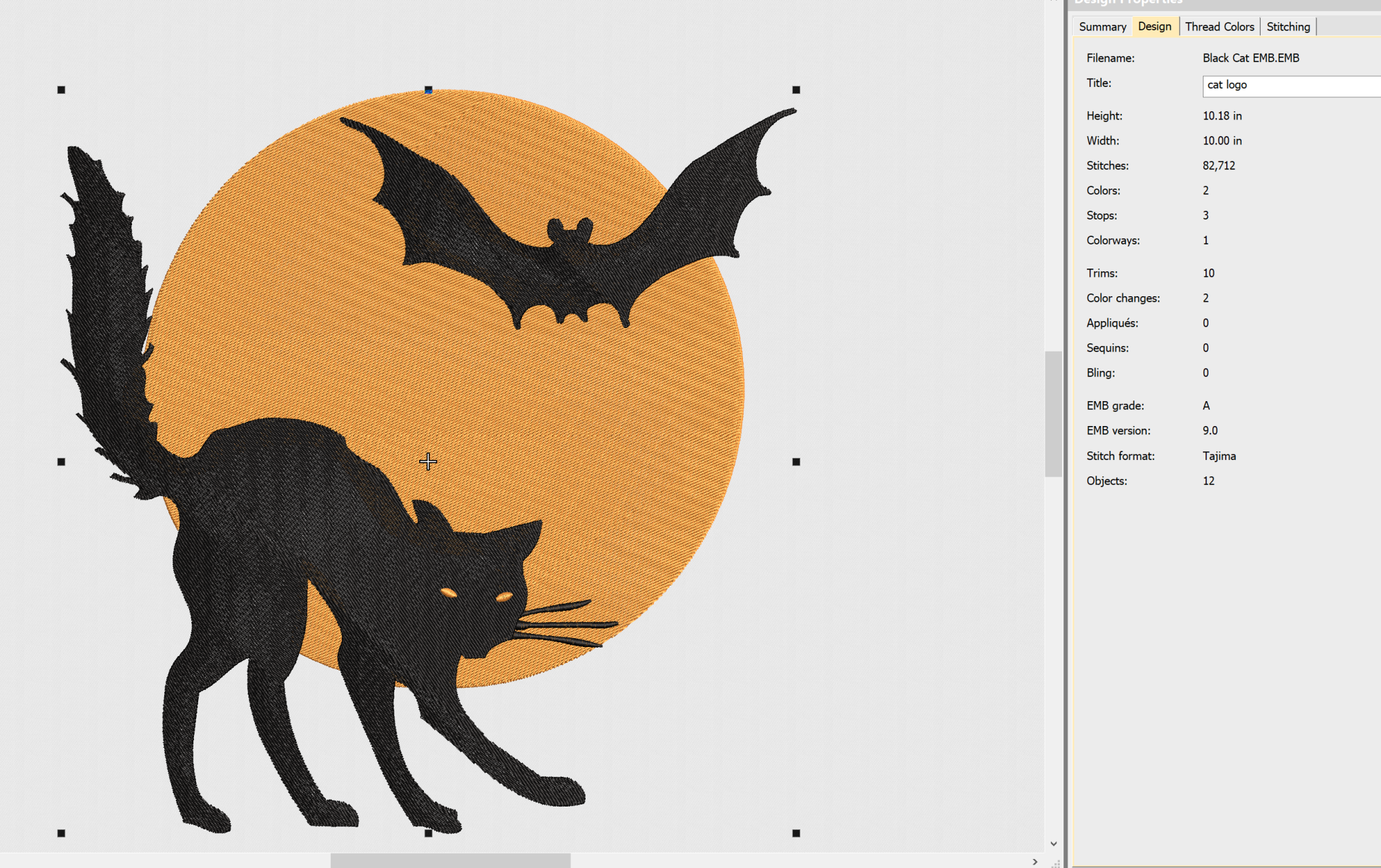

Choosing the Right Design for Fleece

Due to the nature of the fabric, it’s important to be careful when choosing your embroidery designs for fleece projects. Fleece’s plush surface makes it difficult to embroider small details.

Instead, opt for bolder fonts and designs with more simplified details in order to have more clarity in the design that is stitched out on your final product.

However, it’s also important to not choose designs which are too dense. Embroidery designs with a moderate stitch density help prevent excessive perforation of the fleece. Make sure to keep this in mind when digitizing your designs.

Prepping and Choosing a Stabilizer for Fleece

Preparation is crucial to the success of any machine embroidery project, and for fleece, that means taking two steps to make sure your project is a success:

Pre-wash Your Fleece Items

Fleece has a tendency to shrink a bit on the first wash. So, if you do not pre-wash your fleece garments before embroidery you could end up with a distorted design after!

Before you start your embroidery project, was your fleece garments in cold water with a mild detergent. Tumble dry them on low heat to minimize shrinkage.

Choosing the Right Stabilizer

Choosing the right stabilizer for your embroidery projects is also very important. In the case of fleece, consider using cut-away or tear-away depending on the specific type of fleece you’re using.

Hooping Fleece for Embroidery

Fleece is prone to stretching, which can lead to alignment issues. Hoop the fabric with gentle tension, avoiding excessive stretching. Lightly spray a temporary adhesive on the stabilizer to secure the fleece in place without leaving residue.

Tip: For larger projects, consider pin basting the fleece to the stabilizer, ensuring it stays securely in place throughout the embroidery process.

Needle and Thread Selection

It’s also important to choose the right needle size and the right machine embroidery thread weight and type for work on fleece garments. Below you’ll find some recommendations to help you.

Needle Selection

Depending on the type of fleece you’re embroidering on, opt for a sharp or a ballpoint needle. You should choose an appropriate needle size based on the thickness of the fleece.

Larger needles work well for thicker fleece, while smaller ones are suitable for microfleece. Need more help making your selection? Check out our machine embroidery needle guide for more.

Thread Selection

Polyester or rayon embroidery threads are often recommended for fleece projects due to their strength and vibrant colors. Consider using a medium-weight thread to prevent excessive thread buildup and tension issues on fleece.

If you plan to embroider with a specialty thread like metallic, keep in mind that your needle selection may need to change a bit to accommodate this thread’s unique features.

Recommended Machine Settings and Techniques for Fleece Embroidery

The below section is meant to serve as guidelines for fleece embroidery, but don’t be afraid to experiment! In machine embroidery we must test settings ourselves in many cases.

Tension Settings

Experiment with slightly lower upper thread tension settings to accommodate the pile of the fleece. Test on a scrap piece before starting your actual embroidery project. It’s also important Ensure that the bobbin tension is balanced with the upper thread tension to prevent issues like puckering or thread looping on the underside of the fabric.

Speed Settings

Adjust the embroidery speed to a moderate level. Slower speeds can help maintain control and precision. This is particularly true if you’re working with specialty threads like metallic which are prone to breakage and fraying if you’re not careful.

Dealing with Pile and Nap

Dealing with fabrics that have high-pile can be frustrating. Designs tend to sink into the fabric and disappear if you don’t use the right materials and techniques.

Employ cut-away stabilizer to provide additional support for stitches and minimize the impact of the fleece’s plush surface. You can also try Applying water-soluble toppers on the fleece surface to prevent stitches from sinking into the fabric. This is particularly useful for small lettering or intricate details.

PS. This is also a great technique if you’re working on towel embroidery designs!

Minimizing Stretching

Using a stabilizer which is designed for stretch fabrics can help. However, you can also Use temporary adhesives or pins to secure the edges of the fleece and prevent unwanted stretching during the embroidery process.

Dealing with Design Puckering

Opt for a heavyweight cut-away stabilizer to provide ample support and prevent puckering. Ensure proper hooping to maintain fabric tension. Reducing your machine’s embroidery speed can also help minimize your risk of distorting the design, particularly if it’s very dense.

Other Issues During Embroidery

Dealing with any other issues during embroidery such as thread and needle breaks? Make sure to read our machine embroidery for beginners guide and our machine embroidery troubleshooting guide for help with these issues and more.

Barb, our resident quilter and embroidery aficionado, weaves a thread of creativity through our collection. Serving as the curator of machine embroidery content, Barb infuses each design with a touch of her artistic expertise. The free embroidery patterns you discover on our site often bear the mark of Barb’s craftsmanship. Let’s get crafting!