Machine embroidery is a cool hobby that anyone can pick up with a cheap embroidery machine, BUT… all machines need a little help now and then. If your embroidery machine has been giving you trouble this guide should help. We address the most common mechanical and software problems experienced by embroidery machine owners.

Embroidery Machine Troubleshooting

Embroidery Machine Thread Breaks Frequently

If your thread breaks frequently or loops are forming, make sure to check these things.

- Check thread quality: Ensure that you are using high-quality embroidery thread. Some cheaper thread brands are simply more prone to breakage due to the use of lesser materials or less quality control in production.

- Check your thread tension: Adjust the tension settings on the machine to the recommended levels for the chosen thread type and weight. Adjusting simple settings can do a lot to eliminate or at least lessen thread breaks.

- Ensure the thread path is smooth: Check for any snags or obstacles along the thread path. Clean the thread path and guide to ensure smooth movement. Elevating the thread using a thread stand can sometimes help.

- Use a larger needle for heavy fabrics: If working with thicker fabrics, consider using a larger needle to accommodate the thread thickness and prevent breakage. Check our needle chart here.

- Use a needle with a larger eye for metallics: If you’re working with metallic threads, try using a needle with a larger eye. This can help prevent fraying and thread breaks when working with this more delicate thread.

Embroidery Designs Are Puckered

If when your designs are stitched out they “pucker” – here are a few things that could be to blame.

- Try a different stabilizer: It’s possible that your design does not have enough support. Try another stabilizer.

- Check your tension settings: If your machine tension is not balanced puckering could occur. Refer to your machines manual for help balancing the upper and lower thread tension, and try testing on a scrap piece of fabric until you get it worked out.

Embroidery Machine Tension Problems

Do your stitches appear uneven or threads are pulling? Tension could be to blame.

- Balance upper and lower thread tensions: Adjust the tension settings on both the upper and lower threads to achieve a balanced tension. Refer to the machine’s manual for guidance as the setting scan differ depending on the machine brand/model.

- Use the correct needle and thread combinations for the fabric: Ensure that the needle and thread are appropriate for the type of fabric being used. Different fabrics may require specific needle and thread combinations to prevent tension issues.

Embroidery Machine Needle Breaking

If your needles are breaking during embroidery, you could have one of the below problems.

- Check the needle condition for burrs: Inspect the needle for any burrs or damage. A damaged needle can cause breakage and affect stitch quality.

- Ensure the needle is suitable for fabric and design: Use the correct needle type and size for the fabric and design. Thicker fabrics or densely digitized designs may require a larger and stronger needle. For example, when embroidering on leather you’ll need a very sharp needle!

Embroidery Design Is Misaligned

If your design shifts during stitching or appears misaligned – try these fixes.

- Proper hooping and stabilizer usage: Ensure the fabric is hooped securely and that the stabilizer provides adequate support. Proper hooping prevents movement during embroidery. Check our stabilizer guide article for more information.

- Confirm the correct digitization of the design file: Check the digitized design file for errors. Misalignment may occur if the design was not digitized accurately. Re-digitize if necessary.

Thread Bunching or Bird Nesting Under Fabric

Are you having issues with thread bunching, more commonly known as “bird nesting”, where the thread balls itself up under the fabric? Try some of these troubleshooting steps.

- Check your bobbin thread: Ensure the bobbin is wound evenly and inserted correctly.

- Upper thread tension is off: Check and adjust the upper thread tension settings.

- Try Re-Threading: Re-thread both the upper thread and bobbin if issues persist.

Embroidery Machine Is Jamming

If your embroidery machine halts or jams during the embroidery process try these fixes.

- Check for thread snags: Examine the thread path for any snags or entanglements. Remove any obstructions to ensure smooth thread flow.

- Clean the machine and ensure smooth thread flow: Regularly clean the machine, including the bobbin area and thread path, to prevent lint buildup and ensure smooth operation. This is especially true if you work with metallic threads a lot, because they can leave residue inside the machine that will need to be cleaned out.

Embroidery Machine Stops In The Middle Of Embroidery

This one is a little tricky, as it could be a number of things, but I’d try these steps first.

- Check for snags and breaks: First, check to make sure the thread is feeding smoothly and is not snagged or tangled. If the thread breaks, the machine will also stop automatically.

- Inspect The Bobbin: Inspect the bobbin for proper winding and insertion. Please refer to the below “bobbin problems’ section for more on troubleshooting this issue if you suspect it is the bobbin.

- Check the upper thread: Verify the upper thread is correctly threaded.

- Have you done your maintenance?: Ensure the machine is well-maintained and clean. Residue and debris build-up can muck up your machine if you’ve not been doing your regular maintenance.

- Try a restart: Sometimes restarting the machine is enough to make it behave itself. Most modern machines will pick back up right where they left off if they are restarted.

Embroidery Machine Bobbin Problems

If the bobbin’s tension seems uneven or the bobbin thread does not dispense consistently check these things.

- Proper bobbin winding: Wind the bobbin evenly and according to the machine’s guidelines. Uneven winding can lead to tension issues.

- Check bobbin tension and use quality bobbin thread: Adjust the bobbin tension to achieve uniform stitches. Use high-quality bobbin thread for consistent results.

Embroidery Machine Software Issues

If you have issues with transferring designs to the machine there could be several things to blame, but check the below items first.

- Update software to the latest version: Ensure that your embroidery machine software is up to date. Updates may address compatibility issues and improve performance.

- Check USB connections and software settings: Verify that the USB connection between the computer and embroidery machine is secure. Review software settings to ensure correct communication parameters. You may also want to test another USB device, because they can sometimes just die on you.

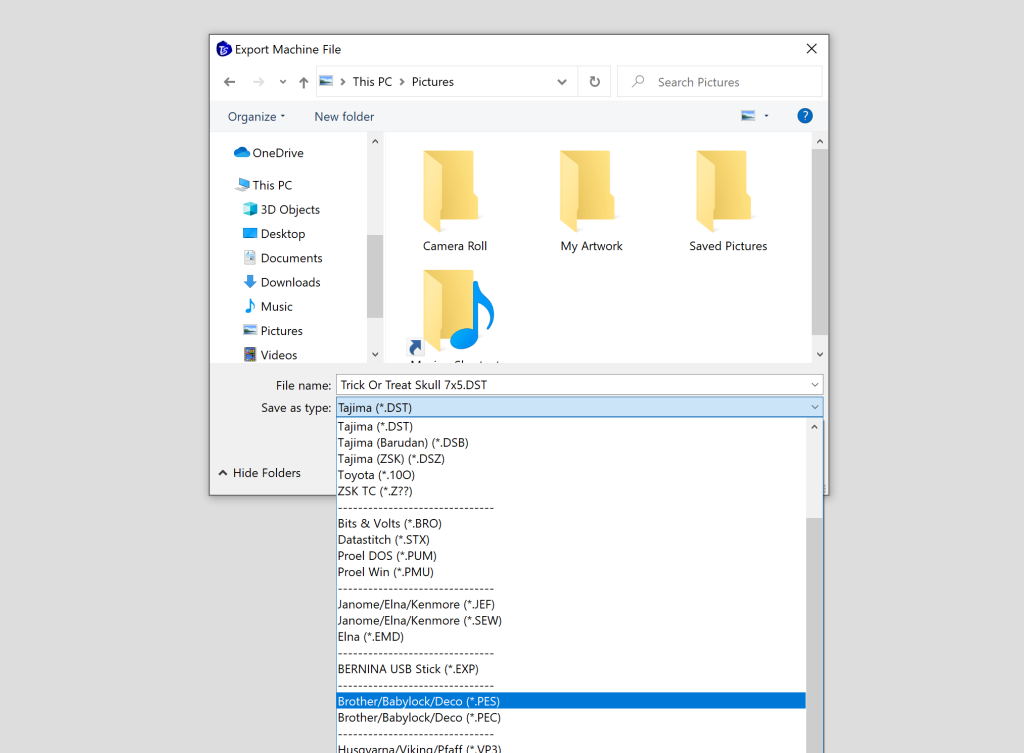

- Double Check design compatibility: Make sure you are transferring the right file. It’s easy to accidentally copy the wrong embroidery file format or a size that is too large for your machine and simply won’t be read.

Embroidery Machine Is Not Reading Design Files

If your embroidery machine is having trouble reading design files there could be numerous reasons. I’ve written a more in-depth article about troubleshooting this specific issue. Read this blog post for more info on designs not showing on machines.

Embroidery Machine Calibration

if your stitches seem off or have irregular lengths, your machine may need to be calibrated.

- Calibrate the machine according to the manufacturer’s instructions: Follow the machine’s calibration instructions in the manual to ensure accurate stitching. Calibration addresses mechanical issues that may affect stitch formation.

- Check for any mechanical issues affecting stitch formation: Inspect the machine for any mechanical problems, such as damaged parts or misalignment. Addressing these issues will enhance the consistency of stitch formation.

Barb, our resident quilter and embroidery aficionado, weaves a thread of creativity through our collection. Serving as the curator of machine embroidery content, Barb infuses each design with a touch of her artistic expertise. The free embroidery patterns you discover on our site often bear the mark of Barb’s craftsmanship. Let’s get crafting!